IK fabrics

Tubeless vs Bladders

Glues and repairs

A ‘PVC vs rubber’ article from 2011 by The Boat People

PVC vs PU vs synthetic rubber: slightly biased. Skip to: 2. Characteristics of the Material

See also: Drop stitch IKs (or more below)

An inflatable kayak differs from a hardshell in many ways. An IK is usually wider and sits higher in the water because the sides and floor are effectively several inches thick, not a few millimetres of rotomolded plastic. Dropstitch (DS) IKs have less thick chambers but are not always slimmer; there’s just more room inside. While length-for-length an IK is lighter than a SinK, it’s rarely as rigid, although DS is close enough. On a short, rock-bashing, creek boat this can either be unnoticeable or even a slight advantage when it comes to impacts.

Here at IK&P we’re more into long IKs of 4m (13 feet) or more. Years of experimentation have proved that this adds up to a do-it-all boat that’s manoeuvrable on rivers up to WW2 and fine for coast hopping up to Force 4. Such a boat can either carry a second paddler or a solo camping payload for a few days touring while rarely weighing more than 18kg or 40lbs and so can be carried over short distances. Problem is, when a round tube IK gets to such a length it can sag in the middle with a single heavy paddler (me?!). There are various ways of making a long IK rigid, but first…

Hull profiles

A hardshell sea kayak can have various hull profiles that, combined with other design elements defines the boat’s stability in various sea conditions. The picture on the left may be merely down to timing but illustrates how a very long SinK on the right runs more level than an IK bobbing about on rough water, partly because the hardshell is heavier and less buoyant, but also because – like a 29-inch MTB wheel – a long, slim kayak ‘flattens out the bumps’ better than a 26-er. Some sea kayaks with V-shaped hull profiles become more stable the rougher seas get, but at the cost of stability in flat water.

The flat and wide hull profile of a traditional tubed IK is not so sophisticated, nor is the boxy profile of a full dropstitch (FDS) IK (right). For better or worse, most IKs are as stable as a raft. The key is to find a balance between reassuring stability and performance-killing width. On an IK I find the optimum width is around 32–27″ (81–69cm). On rivers or at sea an IK hull is usually very stable until things get exceedingly rough. I’d guess that the two hulls pictured left (a red Grabner Amigo and an Incept K40), the less boxy red boat would take more leaning over (or steeper waves) before it suddenly tipped. However, it’s pretty obvious why the grey Incept was some 20% quicker through the water, as was my slender FC Java. Note that the width of a boxy Full DS IK can be misleading as on some boats the flat sides taper in towards the floor. A Sea Eagle Razorlite is listed as 76cm and which is very slim, but some larger paddlers can find it a bit tippy.

The grey Incept was 3.5 inches narrower than the Amigo and has a more pointy bow (its stiff fabric and being 15% longer were also factors). And yet, this 27-inch (67cm) wide Incept could never be described as ‘tippy’ even in seas up to F5-6 (other problems did occur).

It all proves that an IK doesn’t have to be ridiculously wide (as left) to be stable. Many, many otherwise functional-looking IKs are up to a foot wider than the Incept. Even if you are extremely nervous about padding and stability, such width is excessive and makes paddling inefficient.

But the benefits of twin-tubes are clear.

Stability and centre of gravity (CoG)

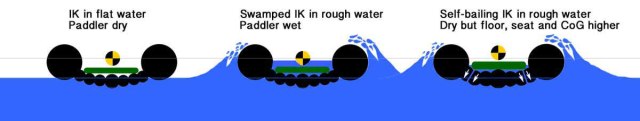

Having said all that, an IK needs to be a bit wider to compensate for the fact, that compared to a SinK or a packraft, you’re sat higher above the water on an air floor and probably on an inflatable seat too (graphic, left). This adds up to a higher centre of gravity which affects stability, just as a 4WD is top-heavy in turns or on slopes compared to a McLaren F1. Your butt is the axis on which you pivot when wobbling/capsizing and on a hardshell, a folder or a packraft you sit just an inch or two below the water level: lower CoG = better stability without resorting to width.

Then, when you factor in less common self-bailing IKs, with an even thicker floor to be above the general water level, again the boat becomes less stable unless it becomes wider. You can see how high the floor appears on the self-bailing AW StraightEdge on the left and the Feathercraft Java, below.

Also, your physique/size can also produce an impression of instability in otherwise well-liked boats that most paddlers find fine. At my XL size, I found my old Gumotex Sunny’s 30″/76cm beam was more than enough and at 27″ my Incept was also fine. But the 28-inch Java (above) and even more so the as wide Mk1 Safari (a self-bailer) were a bit tippy. The graphic below shows a regular IK in calm water and then swamped in rough water (centre). Right is a self-bailer like the Java or StraightEdge which drains in the same rough conditions but requires a thicker floor and/or higher seat to keep you dry. Result: IKs like Java or Safari Mk1 get tippy (for some), or you sit in water (not ideal) or the IK becomes over-wide (also not ideal but the best compromise for white water).

IK floors: I-beam and drop stitch

Traditinal IK hulls had three chambers: two round side tubes and a flatter, wider floor composed of many interlinked tubes (left). And in case you’re wondering, an inflated floor is an important element in an IK’s buoyancy. Obviously, round sided tubes are easy to make and take on the required form on inflation. Providing it’s well made, modest over-inflating is OK as the round profile distributes pressure equally.

The flatter, lilo-like floor is another matter. To make this section the floor is joined top to bottom with I-beam fabric dividers resembling the steel beam on the right. It’s said this is the most labour-intensive and expensive part of traditional IK fabrication and explains why easy, slip-in bladders are preferred by most manufacturers, as on the Java, left. It saves time, effort and cost. Without I-beams or other constraints, once inflated the floor would balloon into a useless rounded form.

But with I-beams too much pressure can pull the floor dividers apart. Result: the floor balloons, the hull becomes deformed and a repair is very complicated or expensive. This is why some IKs including better Aires, some Gumotexes, bigger Grabners and Incept Ks feature a pressure relief valve (PRV) in the I-beam floor. Even though this part of the boat is in the cooling water, it is vulnerable to damage from excessive pressures which can occur when an IK gets hot when left out of the water. Although it had four separate bladders as opposed to an I-beam floor, I learned this lesson the hard way when my day-old Feathercraft Java went Krakatoa on me one sunny day in Colorado.

Following that disaster, one thing I liked about my Incept K40 was it had PRVs on all three chambers. I no longer needed to be paranoid about exploding my £1500 boat by accidentally allowing it to overheat out of the water. I could leave it on a car roof or a beach all day and air would purge harmlessly via the PRVs at the price of being a bit limp once it all cooled down back on the water. A quick blast with the K-Pump was all that was needed. On my Seawave I added PRVs to the two side tubes to get the same benefits.

Other ways of making an IK hull stiff

Whether your IK is supported by inner-tube like bladder (below) or tubeless, one way to achieve a rigid hull is to use twin side beams; two thinner tubes stacked over each other as pictured left. There may not seem much in it, but two tubular sections resist longitudinal bending better than one big tube, and all with a negligible gain in weight. This design also has the advantage of making a slimmer boat compared to a fat, single side tube. There’s more room inside.

Higher sides without width also keep out waves but do make more windage – the bane of IKs. Examples of twin side tube IKs include the Grabner Holidays, Incept Ks as below, and the old Semperit Forelle (the original modern IK).

A cruder method includes fitting metal frames or spars. Advanced Elements offer an optional Backbone (right) for some of their kayaks, though I’m still unsure whether this is as much to impart more of a ‘V’ into the otherwise flabby hull floor and so improve tracking and speed. A picture here, and a forum full of discussions somewhere here. As the picture right at the top of the page shows, the metal frames in the FC Java (see also green graphic above) didn’t keep that boat rigid, at least not with my weight.

This sagging was always a problem on my 13-foot Sunny (left). While paddling in France one time I tried putting a 1-metre plank under the seat to reduce the mid-sag. It did seem to give me an extra inch or two of draught in the shallow river. Later, I tried a couple of straight branches jammed into the cavity between the floor and the side tubes.

My unscientific impression was that by levelling the boat out in the water the Sunny was indeed faster and more responsive. The fact that later on the river sticks popped out of their slots through some rapids suggested how much the 0.2 bar (3psi) Sunny flexed in rough water. Later I tried fitting some chopped-down cheapo paddles. Some form of attachment for the poles needed to be glued to the 3-inch wide flat section where the floor meets the side wall (more here). I got as far as this but then gave the Sunny away. Had I finished the job I’d have expected a little more response to the paddling stroke with a less flex in the waves.

Dropstich

In the last few years, dropstitch (DS) panels have revolutionised IK construction. Advances in this technology are derived from the popularity of inflatable iSuP boards (left) which clearly need more pressure than your average airbed or IK.

Lord knows how they make it, but it’s a way of joining two sheets of coated fabric with countless loose nylon filaments, all the same length (left). When the two sheets are sealed to make a chamber and then pumped up, the space yarn acts like multiple ‘I-beams’, distributing the tension over the entire surface area. Result: pressure can be over 10 psi or nearly 0.7 bar’ – four times than a tubed IK, making the boat much more rigid. More on DS IKs here.

This fabric is Selytech DS PVC developed by Woosung in South Korea. Woosung is the world’s biggest manufacturer of IKs and sell their own boats as Zebec Pro (Z-Pro and KXone). Bic Yakkairs are made in Vietnam but probably use Selytech too. Most of the rest are assembled just over the Yellow Sea in and around Shandong, China. Once they reach western markets, FDS IKs typically go from around £700 for a double.

Dropstitch flat panel limitations

The problem is, compared to a hardshell made around a mold, a kayak made from three flat panels is as crude as a kayak made from a series of parallel inflated tubes. While full DS makes a kayak very rigid, the smooth, flat underside and basic, box profile may make handling in rougher water tricky. One side benefit of the I-beam floors on ‘tubeless’ IKs is the channels formed by the parallel tubes create a keel effect.

They are only just finding ways of making a DS panel that’s anything other than flat as an ironing board. The Decathlon Strenfit X500 (above) marks a big step forward in IK design. The Gumotex Rush (DS hybrid) had also upped the game as has the Advanced Elements AirVolution. More than just the planks making a paddling box, Gumotex have managed to integrate DS panels into the bow and stern, giving a more hydrodynamic form on the sides. AE have managed to make a two-plank sandwich.

Dropstitch is the future of IK design and I wouldn’t be surprised if it somehow moves towards packraft floors too. Longer boats like my old Nomad S1 could benefit from the added support of a separate DS floor.

The Inflatoplane

Incredibly, in the late 1950s Goodyear used the same DS technology to design an experimental inflatable aircraft, the Inflatoplane (left). A light and portable plane, not an inexpensive inflatable decoy as armies have used previously.

It did actually fly but was abandoned when a valid military use for ‘an aircraft that could be brought down by a well-aimed bow and arrow‘ couldn’t be found.