Gumotex Rush (DSF)

See also:

More about Hybrid IKs

Interesting discussion

Another detailed online review

Gumotex are moving on up with hybrid dropstitch technology, originally showcased in 2019’s Thaya which is basically an old Solar 3 with a DS floor to make it more stiff. The new-for-2020 Rush 1 and 2 (left) is quite a sophisticated advance on a DSF or hybrid IK.

The Rush models came out in April 2020, just as the pandemic hit and lockdowns, shutdowns and slowdowns spread across the world. It’s also said there was some kind of quality control calamity at the Gumotex factory which led to many completed boats getting shredded. As a result, stock of Gumotex IKs dried up at a time when post-first-lockdown IK demand went ballistic RTW.

Other IKs gradually came back online, including other Gumotex models, but oddly, the all-new flagship Rush was put right to the back of the queue until 2023. I speculated this may have been a production issue and it seems I was right: I read in the PaddleVenture review comments:

“There is actually a modification to the Gumotex Rush [for 2021]. The drop stitch area on the bow and stern elements is said to have been improved. Apparently there were more complaints here than usual, so that at the end of last summer no more Rush models were produced and this part of the boat was revised”.

It’s not clear what the problems were, but it proves that making anything other than a flat, DS plank is tricky but also that any boat which can get round this (like the Itiwit X500) will be superior. The Rushs were briefly back in stock in 2021 by which time all Gumotex IKs received a massive price hike which killed demand. The R2 is now listed at nearly €1999 (around £1730).

‘Hybrid’ is a cool word for a kayak which isn’t a Full DS like a Sea Eagle Razorlite and many others. These IKs are assembled from three flat dropstitch panels making boxy hulls which, according to the graphics on this page of the French Gumotex importer, can be sub-optimal in choppy waters.

Me, I also think a totally flat, barge-like floor doesn’t help, but the Rushs get round this with raised side tubes which act more like stability pontoons, a bit like the Tributary Sawtooth.

In addition you’ll see on the left the suggestion that tall, flat sides are more affected by waves and wind, which does seem plausible. Of course, if you only every intend to paddle flatwater on calm days, this doesn’t really matter.

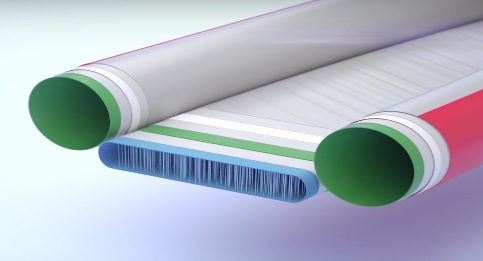

Derived from iSuP boards, DS has become a blessing to IK floor design which hitherto had to use I-beams of parallel tubes (left) which complicates assembly and is prone to ruinous rupture if over-pressured, unless fitted with a PRV or the IK is exceptionally well made.

A Gumotex hybrid IK (below) retains the regular round side tubes of a classic IK for better secondary stability (afaiu) but features a DS floor for much-needed rigidity. However, unique to Gumo, DS end-panels are also used on the bow as well as shorter and less obvious panels at the stern.

A word about this fabric paraphrased from here:

“Nitrilon-Dropstich is composed of a core of 1100 dtx polyester fabric made up of two sheets joined by a mass of threads exactly 10 cm long. Unlike regular PVC-based iSuPs and DS kayaks, the durable elastomer plastic coating is not glued to the fabric, but ‘pressure-impregnated’ which eliminates delamination risks more common with bonded PVC coatings. An additional layer of polyester-reinforced Nitrilon is vulcanised to the floor bottoms making them double thickness.”

The Rushs differ from the Thaya (1st gen Gumo DSF) with the panels forming a more ‘hydroformed’ bow, another weak point with regular blunt-nosed tubed IKs. The Rush’s bow makes a water-slicing wedge sharp enough to cut ripe avocados.

The semi DS sidetubes are more complex than a DS floor attached to two round side tubes (like the Thaya and some Aquaglide IKs, for example) and explains the high price.

The vital stats on the tandem Rush 2 are said to be 4.2m long x 82cm wide. Compare that to my Seawave at 4.5 x 78cm; the Seawave has an 11% better length/width factor (LWF) of 5.77 vs 5.12 over the Rush 2, but those are my Seawave measurements. The side tubes are said to be 19/20cm on the Rush compared to 22 on my Seawave. This and the length may contribute to the load rating dropping to 195kg vs 250 on the longer Seawave. That’s still plenty, unless you’re hauling a moose carcass out of the Yukon.

The official weight varies between 15.5 or 17kg, depending on where you look online. The higher figure is the same as my modified Seawave with a packraft seat mod.

Pressures are another obvious difference with the Seawave. The 6cm DS floor runs at 0.5bar (7.2psi), actually a modest level for DS, but an IK doesn’t need to be as stiff as a iSuP board. The slimmer side tubes run 0.25 bar or 3.75psi (same as the Seawave). Well, that’s according to the table from the online manual shown below. Many outlets still list 0.2 sides and so did the Gumotex website until I corrected them.

0.25 is a bit higher than normal IK pressure, but not quite as high as 0.3 in a Grabner, a Zelgear Spark or the 0.33 bar on my modified Seawave. When you combine that with the stiff DS floor, the 0.25 sides must make the Rush IKs Gumo’s stiffest IKs by far. The difference is, I added PRVs to my Seawave sides before running them at 50% higher pressure to automatically protect them. The Rushs don’t have any PRVs which explains the warning in the manual, above right. It’s odd but worth remembering that my super-stiff Grabner Amigo didn’t feature any PRVs either, not even in the floor. Quality of construction (gluing assembly) must have a lot to do with it.

When you add any colour you want as long as it’s black, you do wonder if no PRVs is a good idea, because in the sun black things get hotter, faster. Black may be great for Cockleshell saboteurs, not so good for visibility at sea and it kills photos stone dead.

It’s true the Innova-branded Swings in North America have long had black hulls and no one complained. But they only run 0.2 bar so need help in stiffening up in the hot sun. They also have fixed decks in red. Many Grabner IKs are now made with black exteriors too (right).

One assumes the Rush’s grey, lowish-psi floor will handle increased pressures from passive solar heating, especially as it’s in the water most of the time. But the black side tubes will get taught which becomes a nuisance to manage (or worry about), even if tubes/cylinders handle high pressures better than flat slabs.

In fact, as you’ll see from the comments below and elsewhere, Gumotex have found black is not notably worse than red or green in absorbing solar heating and dangerously over-pressurising. And if you’re that worried it would be just as easy to install PRVs in the Rush side tubes, as it was on my Seawave.

Because a DS floor is flat, one imagines it will hinder effective tracking, despite having a skeg at the back. The flat hull will plane over the water and wander off to the sides like a packraft – the so-called ‘[windscreen] wiper-effect’.

So, similar to Sea Eagle‘s patented NeedleKnife Keel™ (right), Gumo added a more discrete ‘keel hump‘ under the bow (left) to compensate for the lack of old-style parallel I-beam floor tubes which added a directional element. You can see from the overhead image above that this keel hump is mirrored on the floor inside the boat, either by design or need. This protuberance makes a high-wear point on the IK in the shallows so it’s just as well the floor is double thickness Nitrilon, as mentioned above. It’s the same on any boat. On my Seawave I pre-emptively added a protective strake – a strip of hypalon – to the central tubed rib, though to be honest it never got much wear as I try and be careful. Mine was hardly worn in five years of mostly sea paddling.

Rushs can be fitted with optional decks (green on the R1, above, red on the R2, below), using the same velcro system as the Seawave, with those horribly bulky alloy spars (right) supporting the decking (surely a flexible rod like tentpole material wouldn’t be hard to make). I read on other reviews that they’ve greatly improved the coaming (hatch rim) so that spray skirts attach more securely.

In the still on the right the footrest appears to be the usual rubbish black cushion adjusted by strap and seats can be moved to a variety of positions, too, but the other images show grey footrest tubes which are supposedly dropstitch – much better.

Seats are now solid foam, but the base looks too thin and low to me. A stiff foam backrest (with side bracing straps) is good, but an inflatable seat base is much more comfortable to sit on because you can vary the pressure and so the height. Foam eventually loses its cushioning but an inflatable seat doesn’t need to be made of hefty hull-grade hypalon, as on other Gumo IKs (more in the vid below). But anyway, a seat is easily changed to suit your prefs. More on IK seats here.

Below, a review of a Rush 1 by Austrian Steve. Can’t understand a word but some observations: I like his convertible Eckla Rolly trolley/cart/camp chair; also love the lovely long canoe chute at 20:40. Have to say though, I winced a bit at some boat dragging here and there. Do the right thing, Steve; it only weighs 12kg! Note also this shortish boat seemed to track pretty well without a skeg – the frontal keel-hump may be effective in leading it by the nose, after all. But in the comments Steve admits the stiff, flat floor slaps down hard on wave trains coming out of rapids and I suppose would be the same at sea. It’s a drawback of flat, raft-like DS floors.

See this for an easily translatable written review also in German.

The price of a 2021 R1/R2 has now jumped to a staggering €1417/1999, plus decks going from €410 (solo; R2). There’s also a rudder kit (€289) which is the same as the Seawave unit.

As you can see, I have been comparing the Rush 2 with my 5-year-old Seawave and wondered if it might be time (or an excuse) to change. An unprecedented five years of ownership proves there’s nothing wrong with my Seawave [I sold my Seawave in May 2020 but bought another in October].

What are the benefits of a Rush 2? Black is not such an attractive or useful colour for a boat, and neither is losing a foot in length or 50kg in payload over the Seawave – at least at sea. On a river the greater nippiness from less length will have benefits, but for that I have a packraft. As for greater rigidity, it looks pretty good in this clip but my adapted HP Seawave was very good compared to the lower-pressure Gumboats, and it seems the speed (see below) is no greater, but the gliding effort is reduced. There was talk of a Seawave with a DS floor out in 2022, but that well also be approaching Grabner prices.

Good owner’s review (in French)